Let’s continue story about assembling engines mix of Honda CB750 Seven Fifty CBX750. So, everything was ready to engine halves joining.

I barely had time to pick my camera, so many thanks to Oksana for photos she shot.

I applied sealant to mating surfaces:

And used my little trick to make halves assembling easy. I never liked to play those games when you put gearbox in upper case and then try to aim all shift forks into grooves, so long ago I found little solution: I put gearbox in lower crankcase, checked that all works properly and then strapped gearbox to case with plastic tie.

And used my little trick to make halves assembling easy. I never liked to play those games when you put gearbox in upper case and then try to aim all shift forks into grooves, so long ago I found little solution: I put gearbox in lower crankcase, checked that all works properly and then strapped gearbox to case with plastic tie.

Thus lower crankcase became a bit heavier, but much more easy to operate due installation process.

Thus lower crankcase became a bit heavier, but much more easy to operate due installation process.

It was time to tighten lower bolts in few steps, according to pattern indicated in manual and with proper final torque.

It was time to tighten lower bolts in few steps, according to pattern indicated in manual and with proper final torque.

And tightened upper bolts. Sometimes, when you tighten bolts, engine tries to rotate. To prevent such effect I use my another little tip – 10mm rod installed in engine mounting holes. A couple of tubes of larger diameter thrown over the rod make it push in the ribs more gently.

And tightened upper bolts. Sometimes, when you tighten bolts, engine tries to rotate. To prevent such effect I use my another little tip – 10mm rod installed in engine mounting holes. A couple of tubes of larger diameter thrown over the rod make it push in the ribs more gently.

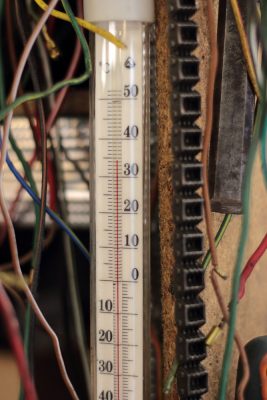

At this time temperature inside of my garage rose up to 35C (95F). Quite uncomfortable for active work, but I continued my job , only forgot to shoot photos frequently.

At this time temperature inside of my garage rose up to 35C (95F). Quite uncomfortable for active work, but I continued my job , only forgot to shoot photos frequently.

So, if shortly: I changed all seals in gearshift and sprocket covers by new OEM and installed them on their places. I used CBX750 sprocket cover, as I decided to use CBX clutch with hydraulic drive.

So, if shortly: I changed all seals in gearshift and sprocket covers by new OEM and installed them on their places. I used CBX750 sprocket cover, as I decided to use CBX clutch with hydraulic drive.

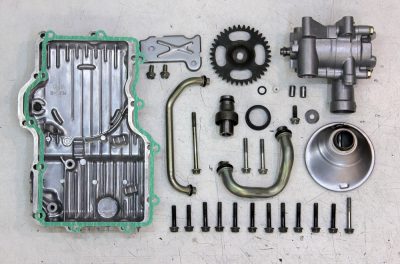

Next point was oil system installation. Seven Fifty oil pump has better performance than CBX750 pump, so I used it as well as other components. Here they are, ready for assembling:

Next point was oil system installation. Seven Fifty oil pump has better performance than CBX750 pump, so I used it as well as other components. Here they are, ready for assembling:

I get from packages with OEM gaskets another portion of new O-rings/seals and installed all components:

I get from packages with OEM gaskets another portion of new O-rings/seals and installed all components:

Final touch: oil pan was on its place too.

Final touch: oil pan was on its place too.