So, frame was given into paint shop, thus I had to prepare last portion of parts for painting as well as for polishing. These were mostly aluminum chassis’ parts, only few steel details were between them too, therefore they had to be stripped from old paint by glass blasting.

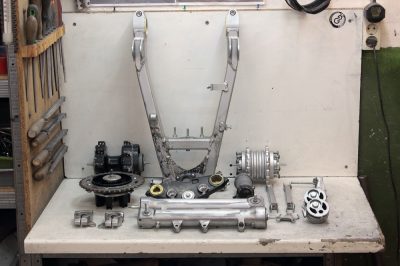

As usual, I firstly cleaned all parts from grease and then protected all places, which in my opinion needed to be protected even from such gentle treat as glass beads blasting. There is no need to describe those processes in more detail, let’s better go directly to the photo of pile of prepared parts.

Glass blasting workshop is places in some 20km from my garage, so I checked if I didn’t forget anything before I transported all parts there. Those guys have two chambers for glass beads blasting. One of them has enormous dimensions and equipped by powerful blaster and special moving scrapers under the flooring to remove used glass beads. Another one is smaller and has a hand blaster. And turned out that I needed both of them, as coating on rear wheel hub and sprocket hub was tough and even with usage of more powerful blaster it went from parts slowly. I had nothing to do while parts were processed, so I shot some short video about how glass bead blasters work.

Glass blasting workshop is places in some 20km from my garage, so I checked if I didn’t forget anything before I transported all parts there. Those guys have two chambers for glass beads blasting. One of them has enormous dimensions and equipped by powerful blaster and special moving scrapers under the flooring to remove used glass beads. Another one is smaller and has a hand blaster. And turned out that I needed both of them, as coating on rear wheel hub and sprocket hub was tough and even with usage of more powerful blaster it went from parts slowly. I had nothing to do while parts were processed, so I shot some short video about how glass bead blasters work.

It took two hours to clean all parts, but result looked quite magnificent. Keen eye may catch little modification I made to fork top yoke or front wheel hub, but about them I’ll write a bit later:-)