I prefer to paint aluminum parts as soon as possible after glass beads blasting. So in the very morning of the day when I have to give cylinder to painter I mounted it to my Zephyr and rode some 20 km to glass beads blasting workshop. I was lucky: they took it in work immediately, so I didn’t have to wait for long, and relatively soon I was on my way back. I always take couple of pairs of new nitrile gloves with me when I bring parts for media blasting, thus after blasting I treat parts that will be painted only in gloves to keep them free of grease.

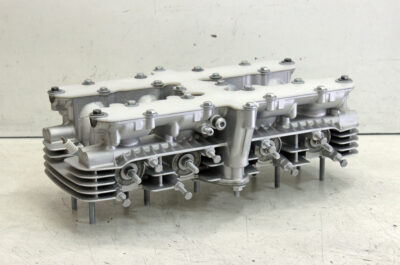

This time there was not much of difference between parts “before” and “after” glass blasting which is no wonder for new part.

This time there was not much of difference between parts “before” and “after” glass blasting which is no wonder for new part.

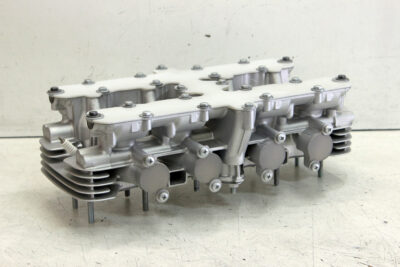

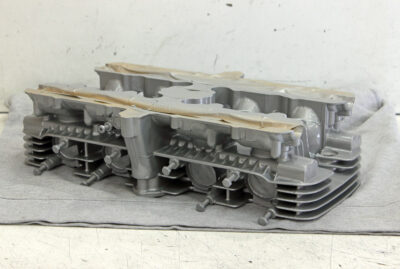

I removed all covers and plugs, then “stretch filmed” cylinder head again and brought it to pain shop where it was painted with Eastwood Ceramic Engine Paint (Color: Universal Aluminum). I let cylinder head to dry for couple of days before I returned it to my workshop. My recommendation is to transport freshly painted parts wrapped in paper (to use paper as first layer of package). In case of storage or long time transportation all next layers of packaging also have to be penetrable for still evaporating solvent and do not react with it.

I removed all covers and plugs, then “stretch filmed” cylinder head again and brought it to pain shop where it was painted with Eastwood Ceramic Engine Paint (Color: Universal Aluminum). I let cylinder head to dry for couple of days before I returned it to my workshop. My recommendation is to transport freshly painted parts wrapped in paper (to use paper as first layer of package). In case of storage or long time transportation all next layers of packaging also have to be penetrable for still evaporating solvent and do not react with it.

Eastwood Ceramic Engine Paint being used with its activator give 3/4 gloss surface. Fortunately it will reduce to semi gloss (mostly satin) after drying and baking. What else I could say about this paint? I like that shade of silver.

Eastwood Ceramic Engine Paint being used with its activator give 3/4 gloss surface. Fortunately it will reduce to semi gloss (mostly satin) after drying and baking. What else I could say about this paint? I like that shade of silver.

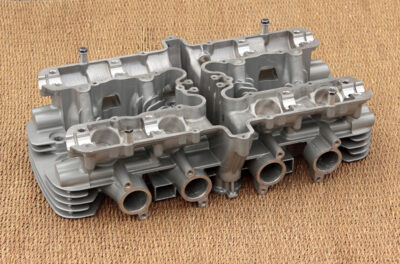

Cylinder head will lay drying on the shelf for another week. Meanwhile let’s talk about valve covers. The thing is that KZ750 (as well as later models of KZ650) cylinder heads unlike to early KZ650 heads have casts for emission control system channels. In bikes intended for countries without emission control those channel remained non-drilled and therefore cylinder head covers have kind of cap protrusions to cover casts on cylinder heads.

Cylinder head will lay drying on the shelf for another week. Meanwhile let’s talk about valve covers. The thing is that KZ750 (as well as later models of KZ650) cylinder heads unlike to early KZ650 heads have casts for emission control system channels. In bikes intended for countries without emission control those channel remained non-drilled and therefore cylinder head covers have kind of cap protrusions to cover casts on cylinder heads.

Original cylinder head of my KZ650 is of early type and has no casts for emission control and therefore its cover has no “caps”.

Without those caps bare casts on cylinder head look quite inaccurate so I decided to buy KZ750 valve cover.

Without those caps bare casts on cylinder head look quite inaccurate so I decided to buy KZ750 valve cover.

When it arrived I found out that main difference between KZ750 and KZ650 covers is not pins for upper cam chain’ guide (easy to remove in fact):

When it arrived I found out that main difference between KZ750 and KZ650 covers is not pins for upper cam chain’ guide (easy to remove in fact):

, but different design of camshaft ends:

, but different design of camshaft ends:

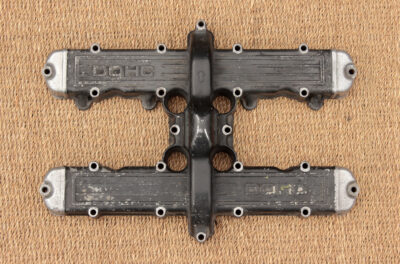

And it turned out that I like design of KZ650 valve cover so much, that I couldn’t force myself to install KZ750 valve cover on the engine of our project. At this point you may assume me to be mad, but for me it was just a matter of fact: I needed to work out other solution. So I dug for information dipper and found out that there was KZ650 valve covers with design similar to early ones but with caps for emission control system’ casts. They were quite rare and those for sale were mostly all in Canada (it seems they were designed for Canadian KZs), however I managed to find couple of them in Europe. It took some time to find suitable valve cover as most of them looked even more oxidized than original valve cover of our engine, but in the end I found what I needed in Austrian ebay. That valve cover was already media blasted (glass beads- or vapor-blasted) and looked pretty decent. Here are photos of it as it arrived.

And it turned out that I like design of KZ650 valve cover so much, that I couldn’t force myself to install KZ750 valve cover on the engine of our project. At this point you may assume me to be mad, but for me it was just a matter of fact: I needed to work out other solution. So I dug for information dipper and found out that there was KZ650 valve covers with design similar to early ones but with caps for emission control system’ casts. They were quite rare and those for sale were mostly all in Canada (it seems they were designed for Canadian KZs), however I managed to find couple of them in Europe. It took some time to find suitable valve cover as most of them looked even more oxidized than original valve cover of our engine, but in the end I found what I needed in Austrian ebay. That valve cover was already media blasted (glass beads- or vapor-blasted) and looked pretty decent. Here are photos of it as it arrived.

As you may see it’s similar to early cover but have “caps” to cover aforementioned casts on cylinder head.

And while I was comparing all covers and fit them to cylinder heads I found out that there is third difference between KZ650 and KZ750 covers: the distance between holes of their front and rear bolts is different. In fact KZ650 cover for 3mm shorter than KZ750 cover.

All valve cover holes have 7mm of diameter and for KZ650 center-to-center distance between rear and front holes is 255mm while for KZ750 it’s 258mm. On practice it means that I have to machine both holes on KZ650 valve cover for one millimeter each to install it on KZ750 cylinder head. However it’s not a big deal.

All valve cover holes have 7mm of diameter and for KZ650 center-to-center distance between rear and front holes is 255mm while for KZ750 it’s 258mm. On practice it means that I have to machine both holes on KZ650 valve cover for one millimeter each to install it on KZ750 cylinder head. However it’s not a big deal.