Remember this nice KZ750 cylinder head that made long way to me from USA through Germany?

I cleaned it, I checked all I could, I found out that two from four exhaust valves were slightly bent, thus out of game. Then, as usual, I gave it to specialized workshop that has professional NC machines to renovate valve seats and do all specter of works with cylinder heads, valves, cylinders and so on, and so forth. To avoid any misunderstanding I (again, as usual) brought service manual and clearly indicated specs for valve seats. And that’s the point where I got completely unexpected result: firstly they cut wrong shape and then, trying to fix this issue they cut valve seat too deep, thus installed valve height was out of specs for all valves. Simple calculation showed that valve end grinding will do no good, there was no enough of end to grind. My mistake was trusting that workshop. Thus, when I gave head in work I didn’t indicate actual installed valve height or even acceptable diapason of measurements, so their misdoing cost nothing for them and wrecked cylinder head for me.

I cleaned it, I checked all I could, I found out that two from four exhaust valves were slightly bent, thus out of game. Then, as usual, I gave it to specialized workshop that has professional NC machines to renovate valve seats and do all specter of works with cylinder heads, valves, cylinders and so on, and so forth. To avoid any misunderstanding I (again, as usual) brought service manual and clearly indicated specs for valve seats. And that’s the point where I got completely unexpected result: firstly they cut wrong shape and then, trying to fix this issue they cut valve seat too deep, thus installed valve height was out of specs for all valves. Simple calculation showed that valve end grinding will do no good, there was no enough of end to grind. My mistake was trusting that workshop. Thus, when I gave head in work I didn’t indicate actual installed valve height or even acceptable diapason of measurements, so their misdoing cost nothing for them and wrecked cylinder head for me.

I didn’t wish to meddle with valve seat replacing so I decided to buy another KZ750 cylinder head. I found one in Austria with description that “mileage is around 10000 km and nothing is bent, broken and all was working up to the moment of disassembling”. We asked seller if this information is true and he confirmed and even sent us photo of KZ750 clocks with some 14K km on it. Soon I received the parcel with that cylinder head. And guess what?

I didn’t wish to meddle with valve seat replacing so I decided to buy another KZ750 cylinder head. I found one in Austria with description that “mileage is around 10000 km and nothing is bent, broken and all was working up to the moment of disassembling”. We asked seller if this information is true and he confirmed and even sent us photo of KZ750 clocks with some 14K km on it. Soon I received the parcel with that cylinder head. And guess what?

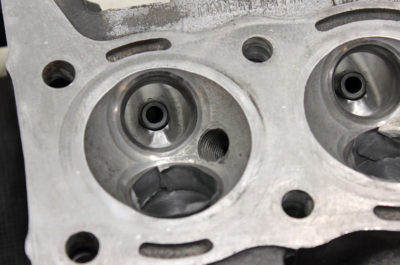

Part of exhaust valve seat of fourth cylinder was chipped.

I was completely disappointed but I decided to make a third try and ordered yet one KZ750 cylinder head. This one, as well as previous was factory painted in black. Black cylinder heads have not only different part number to that of silver cylinder heads, but also were cast in different mold. Their intake ports are slightly less accurate than those of silver cylinder heads.

I was completely disappointed but I decided to make a third try and ordered yet one KZ750 cylinder head. This one, as well as previous was factory painted in black. Black cylinder heads have not only different part number to that of silver cylinder heads, but also were cast in different mold. Their intake ports are slightly less accurate than those of silver cylinder heads.

These imperfectness was the reason why I’ve been slightly carried away when working on cylinder head. I started it like cleaning but then it turned… no, couldn’t call it porting. Shaving is more close to what I did to intake and exhaust ports.

These imperfectness was the reason why I’ve been slightly carried away when working on cylinder head. I started it like cleaning but then it turned… no, couldn’t call it porting. Shaving is more close to what I did to intake and exhaust ports.

Now this very cylinder head is in another specialized workshop for valve seat work and surface grinding. Keep my fingers crossed hoping the work would be done properly this time.

Now this very cylinder head is in another specialized workshop for valve seat work and surface grinding. Keep my fingers crossed hoping the work would be done properly this time.