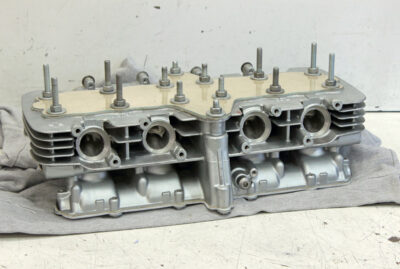

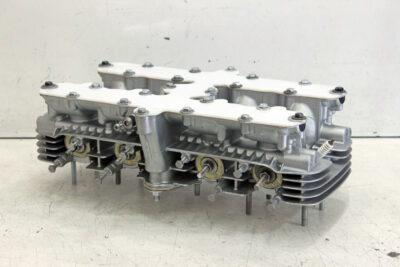

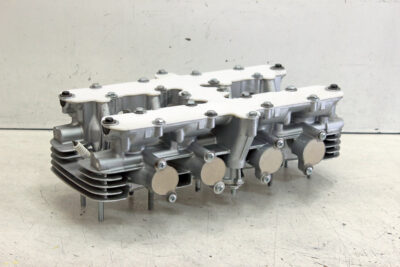

My next task with cylinder head was to prepare it for glass beads blasting. Why to bother with blasting if head is new? For one thing, 1980 KZ750 cylinder head is factory painted. The shade of silver paint is mostly completely corresponds those of bare head. However, when one wipe cooling ribs with rag soaked in carburetor cleaner one may see traces of paint on rag. Another reason is that media blasting is the only way to be sure that paint will be applied on bare and non oxidized aluminum.

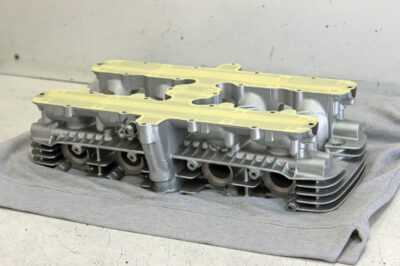

But danger of media blasting is media itself that in case of cylinder head with its blind ends of oil channels may cause havoc if even remains of it were left in some corner inside. So when I pack cylinder head for glass beads blasting I pack it tight. I pack all valve tappets’ wells with rags and closed all oil channels on upper side of head with paper tape. Then I sealed upper end of cylinder head with paper tape. I used old camshaft end plugs and I didn’t forget to seal tachometer port with piece of fuel hose with bolt in it.

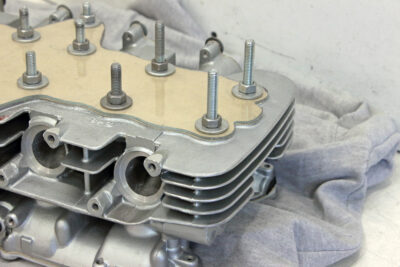

Next layer is cardboard gasket:

Next layer is cardboard gasket:

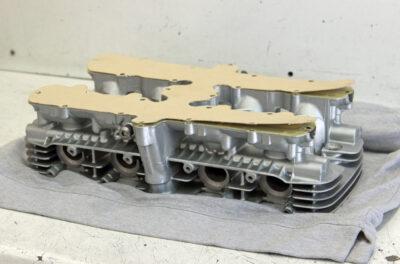

Usually I use original valve cover as upon cardboard gasket, but configuration of KZ650-KZ750 valve cover may complicate the work of blaster, so I made cover from plastic I had at hand (some kind of monolithic PVC I suppose).

Usually I use original valve cover as upon cardboard gasket, but configuration of KZ650-KZ750 valve cover may complicate the work of blaster, so I made cover from plastic I had at hand (some kind of monolithic PVC I suppose).

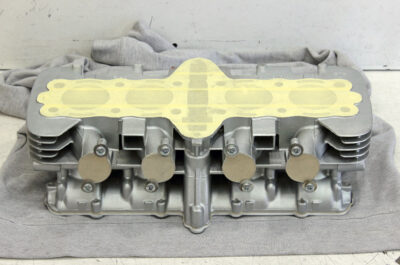

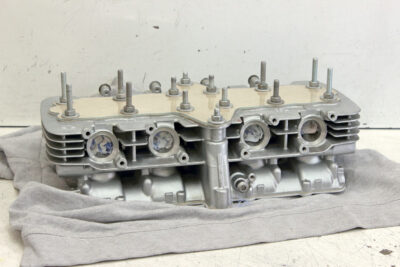

I “rag protected” intake channels:

I “rag protected” intake channels:

Then I applied to them paper tape:

Then I applied to them paper tape:

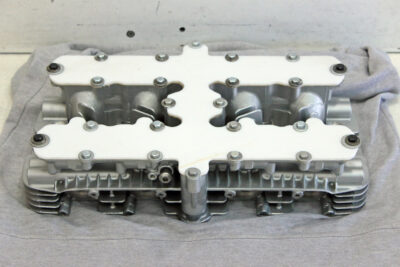

And similarly to top I covered them with cardboard gaskets and PVC covers (this time transparent).

And similarly to top I covered them with cardboard gaskets and PVC covers (this time transparent).

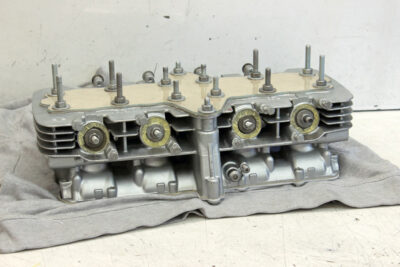

Same procedure I applied to the bottom of head (I was careful with oil channels as I want no rag threads left there).

Same procedure I applied to the bottom of head (I was careful with oil channels as I want no rag threads left there).

Exhaust ports I sealed with rags and plugs made of thick monolithic PVC in combination with paper tape for better sealing.

Exhaust ports I sealed with rags and plugs made of thick monolithic PVC in combination with paper tape for better sealing.

Old spark plugs finished sealing. In result I got something like cylinder head on legs…

Old spark plugs finished sealing. In result I got something like cylinder head on legs…

I bead blasted my kz650 head too and let me tell you, I should have done as much prep and protection as you. Luckily, no machined or precision surfaces were ruined when I did it, but I spent a long time cleaning every surface thoroughly. Tooooook sooooo looooong. Would have saved me hours of cleanup if I had spent a little longer on the prep.

I always prepare engine parts for glass beads blasting. It may take time but it definitely solve the issues of surfaces protection and remains of media inside of engine.

https://www.gazzz-garage.com/2019/08/02/kawasaki-kz650-cafe-racer-engine-part-2/

https://www.gazzz-garage.com/2017/07/05/seven-fifty-cafe-racer-engine-preparation-for-painting-part-1/