Recently received email reminded me that I have had this article mostly ready for a long time. It also motivated me to finish it and shot some pictures to illustrate it.

Well, it’s not a secret that engines of Honda CBX750 (RC17) and Honda CB700SC NightHawk (RC20) and their descendants like Honda CB750 F2 Seven Fifty Honda (RC42) and CB750 NightHawk (RC39) have same roots and are closely related.

So no wonder that early models of CBX750 and CB700SC cause people to ask similar questions. And since they asked me I decided to write this article in addition to my previous comparison of CBX750 and CB750 engines. The subject of this article is the crankshaft oil seal which in early models separated the chamber, where the ignition pulse generators installed, from the main volume of the crankcase. So we could call that ignition chamber “dry”. The issue with this seal is that nowadays when it starts leaking it is mostly impossible to find and buy a replacement for it.

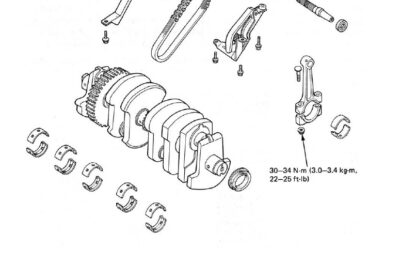

Oil seal in question has dimensions 36x51x8, and part number 91204-MJ0-005. It has a small lip for fixing in the crankcase, therefore crankcase halves have grooves for seal lip. Here are pictures from service manual and Ebay:

However, later on Honda decided to remove the seal, in case of Honda CBX750 it is known that crankshaft seal was installed in engines up to 2008957 serial number. To eliminate a seal, Honda modified CBX750 and CB700SC/CB750SC engines: they removed the ventilation hole of the ignition chamber and connected the chamber with the main crankcase volume by port located in the lower part of chamber, so the chamber became “wet”. They also moved wire intake port on the upper half of the crankcase. If there were any service bulletin about crankshaft oil seal, they never were included in service manuals. Honda CB750 RC42 Seven Fifty and CB 750 RC39 Night Hawk inherited this “wet” chamber from their ancestors.

However, later on Honda decided to remove the seal, in case of Honda CBX750 it is known that crankshaft seal was installed in engines up to 2008957 serial number. To eliminate a seal, Honda modified CBX750 and CB700SC/CB750SC engines: they removed the ventilation hole of the ignition chamber and connected the chamber with the main crankcase volume by port located in the lower part of chamber, so the chamber became “wet”. They also moved wire intake port on the upper half of the crankcase. If there were any service bulletin about crankshaft oil seal, they never were included in service manuals. Honda CB750 RC42 Seven Fifty and CB 750 RC39 Night Hawk inherited this “wet” chamber from their ancestors.

Since I still have CBX750 RC17 crankcase of later type in my basement storage ( as well as CB750 RC42 crankcase), we could take a look at how Honda eliminated crankshaft seal. Here is CBX750 crankcase.

As you might see, the seat for the seal has traces of machining and there is a relief hole for oil that is positioned behind the seal. But there is no groove for seal lip. Port that connects the ignition chamber and main cases volume is clearly visible, and so is the absence of a ventilation hole on the bottom half of the crankcase.

As you might see, the seat for the seal has traces of machining and there is a relief hole for oil that is positioned behind the seal. But there is no groove for seal lip. Port that connects the ignition chamber and main cases volume is clearly visible, and so is the absence of a ventilation hole on the bottom half of the crankcase.

However, please pay attention to the port for wires: its position and design differs from wires input on early models and it is important. We’ll return to it shortly.

And here is a battered case from Honda CB750 RC42 Seven Fifty with repair “masterpieces” from the previous owner. Since I had no use for the crankcase in such poor condition it ended up in the storage. As you might see, this case also has an opening between ignition and main chambers, however the seal’ seat is not machined, and there is no relief hole for it (which is only understandable since there is no oil seal).

And here is a battered case from Honda CB750 RC42 Seven Fifty with repair “masterpieces” from the previous owner. Since I had no use for the crankcase in such poor condition it ended up in the storage. As you might see, this case also has an opening between ignition and main chambers, however the seal’ seat is not machined, and there is no relief hole for it (which is only understandable since there is no oil seal).

And since Honda “factory eliminated” that seal, then so could owners of early CBX750/CB700SC. We even could name such mod as “Factory approved”.

Seal removing modification is not upgrade but update caused by absence of replacement seal. The main advantage of seal removing is that you do it once and have no further issues with seal. As for idea to place other type of seal in place of specific crankshaft seal, here my opinion is next:

I’ve seen quite a lot of Honda, Kawasaki and Yamaha inline four engines which were equipped with one or two crankshaft seals and all of them were of specific design: not all of them had lip to hold them in cases, but most of them were single-direction seals, also called helix seals. What exactly such seals are one may easily google, but the main idea of these seals is to provide less friction during shaft rotation, so they are more energy efficient and have less wear so they last longer. Honda CB700SC/CBX750 crankshaft seal lip has no helical ridges, but the design of seal back side is pretty curious, thus I could assume this seal also might be of low friction type. So, using ordinary seal (even decent one) in place of specific crankshaft seal may cause more extensive wear of both seal and shaft and therefore you might have a need to replace them regularly and periodically. And here we come to the second, but little advantage of seal removing: no seal – no friction.

But, surely, there are some bottlenecks in seal eliminating.

First , one has to drill the hole that will connect the ignition chamber and internals of the crankcase. The best place for it is exactly where the Honda placed it. Dimensions of the original Honda port are around 10x16mm. I would recommend drilling and cutting the opening on the disassembled engine and make it similar to the factory one. Buy the way, you could remove the leaking seal. If you decide to do the modification without engine disassembling, there is always the possibility that part of aluminum shavings will end up inside of the engine.

To minimize the risk of such an event I would only recommend to drill slowly simultaneously with using a vacuum cleaner (maybe with some kind of attachment to get closer to the drill bit). In addition to vacuum cleaner one may also slightly increase air pressure inside of the crankcase by using a compressor and air blow gun. Another trick – applying grease to the drilling area and keeping the drill bit covered in grease (I mean regular cleaning and re-greasing). In combination with low drill RPMs aluminum shavings wouldn’t be flying in all directions and chances that a lot of them end up inside of cases are minimal.

It is also advisable to check output edges of drilled holes and treat them with a small file if necessary (using grease to keep shavings on file). I also recommend to drill holes with the bike on the central stand, then, when work is done, put the motorcycle on the side stand (or just tilt it) so some amount of engine oil will flush through drilled holes. That’s the final measure against shavings in crankcase.

It’s also not hard to calculate that two holes with a diameter of 10mm will be close in size to the original port.

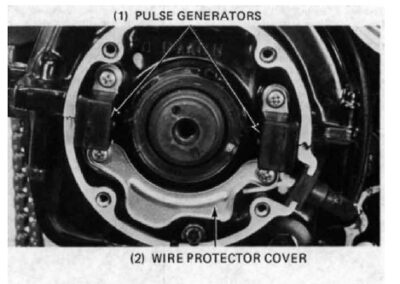

Second potential bottleneck is input of wires. Early CBX750 and CB700SC which utilized a “dry” type of ignition chamber have wires output placed in the lower rear quarter of the crankshaft case. And that output wasn’t meant to serve in conditions of oil mist that fills insides of a crankcase. Here is photos from CBX750 service manual and Ebay:

Second potential bottleneck is input of wires. Early CBX750 and CB700SC which utilized a “dry” type of ignition chamber have wires output placed in the lower rear quarter of the crankshaft case. And that output wasn’t meant to serve in conditions of oil mist that fills insides of a crankcase. Here is photos from CBX750 service manual and Ebay:

Later “sealless” CBX750 and CB700SC engines (as well as CB750s from 90s) were equipped with modified crankcases: the port for ignition pulse generators’ wires was moved to the upper rear quarter of crankshaft case, and designed to fit double sealing rubber. Internal wiring was also moved to the upper part of the chamber, but the protective plate seems to be the same as the early one.

Later “sealless” CBX750 and CB700SC engines (as well as CB750s from 90s) were equipped with modified crankcases: the port for ignition pulse generators’ wires was moved to the upper rear quarter of crankshaft case, and designed to fit double sealing rubber. Internal wiring was also moved to the upper part of the chamber, but the protective plate seems to be the same as the early one.

So, my advice for those who perform seal elimination would be: in addition to drilling oil port, and sealing an air vent hole in the lower part of the ignition chamber, – but also using sealant on wires and input rubber to avoid oil sweating through the rubber.

So, my advice for those who perform seal elimination would be: in addition to drilling oil port, and sealing an air vent hole in the lower part of the ignition chamber, – but also using sealant on wires and input rubber to avoid oil sweating through the rubber.

With all this modification accurately done there is no reason why one couldn’t use his/ her early CBX750 or CB700SC without issue of oil dripping from under the ignition cover. And if you are worried about ignition pulse generators functioning in oil mist, you are also could be confident: they work OK.

Hello, Nazar!

Thank you for sharing your knowledge!

Is it possible to swap earlier type crankshaft case to a newer one?

Will it require any other modifications except ignition pulse generator relocation?

Hello Isken,

Sorry for late reply

Yes, cases from CBX750 without seal could be used instead of cases with seal. Same is with CB700, I assume. However if you mean if engine CB750 Seven Fifty could be installed in a CBX750 frame the answer is more complicated. Rear mounts will fit all OK and so will oil lines. However one needs to make new front engine brackets since CBX750 front mounts are equipped with rubbers while CB750 Seven Fifty mounts have no rubbers.

Hello. I have an 84 cb700, not sure of the sub category but the title says B70 for the model. I’m unable to find the alternator chain drive and the tensioner, every place I tried to purchase it are out of stock. I was wondering if you would know if an other model or year would be interchangeable?

Thank you.

Hello,

I do believe that alternator chain tensioner from Honda CB750 Seven Fifty and NightHawk may fit. As for the alternator chain – CB750 chain is wider than CB700/CBX750 chain:

https://www.gazzz-garage.com/2017/11/27/cbx750-vs-cb750-seven-fifty-engines-comparing-part1-crankcase-internals/ but it may work for CB700.

Thanks for the information on the elimination of the crankshaft seal. It was very helpful.

Thank you for this information. Just finished getting a cb750sc canadian edition up and running after it was sitting for ten years. And the seal starting leaking. Tomorrow I shall complete this mod.

When warm( about a mile ) my 700sc nighthawk splutters, backfires and fires only on 2&3 when 1&4 do not fire. Ticks over fine but does this on revs over 1,000rpm. I replaced plugs, leads, wires, both coils…Still same. Opened side casing to investigate pickup and oil poured out so I cleaned and found oil pumping from behind rotor when revving. Do I replace the crank seal or is there something deeper I should think about( I’ve read that the seal isn’t possibly the problem?) I would thankyou in advance for any advice bud.