Before I could start assembling the starter motor I had to replace bearing and O-rings. Since O-Rings have part numbers it’s not an issue to buy them.

The bearing of the output shaft is 6003Z bearing. Letter Z or 2Z or ZZ in the end of the ball bearing name means that bearing is equipped with metal shields from both sides (sometimes single Z stands for shield from only one side).

The bearing of the output shaft is 6003Z bearing. Letter Z or 2Z or ZZ in the end of the ball bearing name means that bearing is equipped with metal shields from both sides (sometimes single Z stands for shield from only one side).

The KZ650 starter bearing looks like it was intended to have two shields (there is a groove for the second shield), but had one of the shields removed. It is very important that it has only one shield.

The KZ650 starter bearing looks like it was intended to have two shields (there is a groove for the second shield), but had one of the shields removed. It is very important that it has only one shield.

The fact is the KZ650 starter has oil seal placed right over the bearing. The only bearing shield faces the outer side of the starter cover, and since this shield is non-hermetic, during the work of engine oil mist penetrates it and feeds both: bearing and seal.

The fact is the KZ650 starter has oil seal placed right over the bearing. The only bearing shield faces the outer side of the starter cover, and since this shield is non-hermetic, during the work of engine oil mist penetrates it and feeds both: bearing and seal.

Thus, this bearing couldn’t be replaced with RS (equipped with seals) type of bearing. After some thoughts I chose NSK 6003ZZ C3 bearing.

C3 stands for additional radial clearance, thus such bearings are more suitable for high temperatures.

C3 stands for additional radial clearance, thus such bearings are more suitable for high temperatures.

After I removed one of the covers and washed out grease, the bearing was ready to be installed.

After I removed one of the covers and washed out grease, the bearing was ready to be installed.

As I wrote in a previous post, KZ electrical starters are equipped with three gaskets that have no part numbers and thus couldn’t be ordered. One of them is most significant. I will explain why in the next part of the story. I measured what remains from old gaskets and places where they have to be installed. On the base of these measurements I drew blueprints for gaskets and then ordered them to be laser cut from Gambit AF-OIL gasket sheet (based on Kevlar® aramide fibres, mineral fibres, and fillers bound with NBR rubber-based binder). As I wasn’t sure about gasket thickness, I ordered two sets of different thickness.

As I wrote in a previous post, KZ electrical starters are equipped with three gaskets that have no part numbers and thus couldn’t be ordered. One of them is most significant. I will explain why in the next part of the story. I measured what remains from old gaskets and places where they have to be installed. On the base of these measurements I drew blueprints for gaskets and then ordered them to be laser cut from Gambit AF-OIL gasket sheet (based on Kevlar® aramide fibres, mineral fibres, and fillers bound with NBR rubber-based binder). As I wasn’t sure about gasket thickness, I ordered two sets of different thickness.

To assemble yoke assembly I had to refresh screws that mount field coils’ poles. That screw is pretty specific M6 countersunk screws, as they have heads of diameter smaller than ordinary countersunk screws. Here is original screw in comparison to stainless steel Allen screw:

To assemble yoke assembly I had to refresh screws that mount field coils’ poles. That screw is pretty specific M6 countersunk screws, as they have heads of diameter smaller than ordinary countersunk screws. Here is original screw in comparison to stainless steel Allen screw:

I decided that stainless steel screws will fit such an application, so I modified four of them to replace original screws.

I decided that stainless steel screws will fit such an application, so I modified four of them to replace original screws.

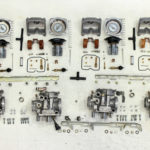

After this everything was ready for assembling. I decided to not replace the original oil seal: for one thing it looked completely intact and for another it has quite a specific configuration of what is in ordinary seal is dust lip. But before I started assembling, sure, I couldn’t but shoot the exploded view of the starter motor.

After this everything was ready for assembling. I decided to not replace the original oil seal: for one thing it looked completely intact and for another it has quite a specific configuration of what is in ordinary seal is dust lip. But before I started assembling, sure, I couldn’t but shoot the exploded view of the starter motor.