Many engine paints require “baking” to complete their curing. Also, it’s better to test paint before the engine is assembled. And even taking into account that the cylinder head will have a higher temperature than the crankcase, it’s advisable to bake the whole engine with a temperature range close to that of the cylinder head. The thing is even high temperature paint may change colour for shade or two being heated to working temperature of air cooled engine’ cylinder head. Thus it’s better to heat the whole engine up to around 160C in advance to avoid an issue of difference in shade between top and bottom of engine.

Now let’s proceed to the methods of engine baking. The method, being well known from various forums, is to bake engine and brake parts in kitchen ovens. But you may find from the same forums that this method may end up in some tension of relation between engine baker and his wife/girl-friend. And sure, not all of us like pizza with the smell of engine paint. As my garage is far from any kitchen oven, I from the beginning had to invent another method to bake the engine. I ended up with an ordinary cardboard box laid out from inside with two or three layers of cooking foil. I laid every layer in direction perpendicular to previous and with each strip of foil overlaying previous. I also use adhesive aluminum foil tape to fix every strip of foil here and there. In result cardboard is well isolated from the heat and thus never reaches ignition temperature even when parts inside of the box are heated up to 160-170C. As a heat source I use a heat gun. And this simple receipt definitely could call it “marriage savior”. Or “pizza savior”…:-) Just don’t forget about safety measures!

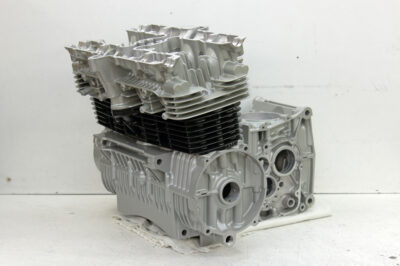

After baking I put the crankcase, cylinder and cylinder head together for the first time. Looks nice so far and will look even better when that half glossiness wears off.

After baking I put the crankcase, cylinder and cylinder head together for the first time. Looks nice so far and will look even better when that half glossiness wears off.

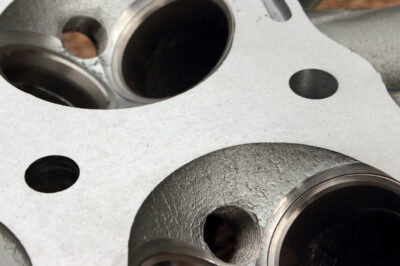

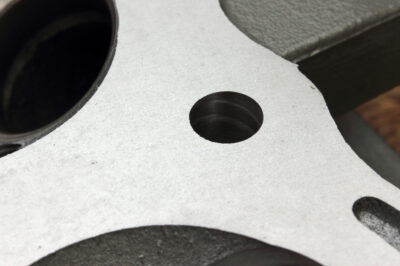

After baking I take cylinder head for resurfacing to the same specialized workshop that successfully bored and resurfaced cylinders for my KZ650. Even being new, the cylinder head had some “storage” warpage (around 0.06mm) and points of corrosion on the contact surface (effect of non-proper storage accomplished by the seller, Siegfried Spängler from Motorrad Spängler GmbH). We took 0.09mm from the cylinder head surface, so the cutter only touched intake valve seats. I could order to take another 0.05mm, but I decided to not go farther, even if some corrosion point still remained. My reasons were based on my expert judgment as follows:

After baking I take cylinder head for resurfacing to the same specialized workshop that successfully bored and resurfaced cylinders for my KZ650. Even being new, the cylinder head had some “storage” warpage (around 0.06mm) and points of corrosion on the contact surface (effect of non-proper storage accomplished by the seller, Siegfried Spängler from Motorrad Spängler GmbH). We took 0.09mm from the cylinder head surface, so the cutter only touched intake valve seats. I could order to take another 0.05mm, but I decided to not go farther, even if some corrosion point still remained. My reasons were based on my expert judgment as follows:

- The points of corrosion that remains are non critical and couldn’t implicit the work of the engine or its assembling.

- Cylinder head could still be decked farther and maybe someone someday will thank me for that.

What I liked and appreciated in the work of the guy from that specialized workshop is that he made all the work with me observing, and the way he tuned his machine: cylinder head surface is shimmering and cutter traces are mostly invisible.

What I liked and appreciated in the work of the guy from that specialized workshop is that he made all the work with me observing, and the way he tuned his machine: cylinder head surface is shimmering and cutter traces are mostly invisible.

Now the engine is mostly ready for assembling, but alas, only mostly. Why? Find out in my next posts.

Now the engine is mostly ready for assembling, but alas, only mostly. Why? Find out in my next posts.