Year 2014 hadn’t brought stability for Ukraine either. But people get used to everything, so in Spring I returned to my project and decided to finish it anyway.

The only few important parts weren’t completed yet. Thus, I designed and made a new version of the front mud guard, chain guard, lower gaiter clamps and pod filters covers. Steering limiter and seat lock base were welded to frame:

And suddenly it turned out that the Cafe-Racer was ready for road testing.

And suddenly it turned out that the Cafe-Racer was ready for road testing.

Firstly bike was tested for steering limiter sufficiency in garages area. My friend, who performed as welder, also has been practicing motorcycle gymkhana. So he just sat on the bike and proved that limiter is good enough:-)

Firstly bike was tested for steering limiter sufficiency in garages area. My friend, who performed as welder, also has been practicing motorcycle gymkhana. So he just sat on the bike and proved that limiter is good enough:-)

After that I had no choice but to organize the Track Day. I involved several friends, including that one, who superbly rides on everything capable to be ridden, and we went to old Kart Circuit. I got a dozen laps at first, and enjoyed my bike so much! It occurred to me, I’ll be better with my camera, whereas my chap – on the Track.

So I took a camera, gave cafe’ key to my friend and Show begun. After a pair of warming laps he ridden like hell.

So I took a camera, gave cafe’ key to my friend and Show begun. After a pair of warming laps he ridden like hell.

I do not actually consider myself a videographer – I am a photographer, in addition my hands were trembling with excitement, but I’ve shot the video the best I could.

I do not actually consider myself a videographer – I am a photographer, in addition my hands were trembling with excitement, but I’ve shot the video the best I could.

The Track Day triggered one of the final project’s stages: total bike repainting and rebuilding of parts, which weren’t rebuilt earlier.

Fuel tank, front mudguard and tail were gone to the painter first, so the question of tank’s logo beaconed automatically. Basically, it could be the Yamaha logo, but what relation it had to the project by the end? Therefore I began designing my own logo. I am not professional designer, but with a couple of friend’s advises and comments I found the right idea and made it.

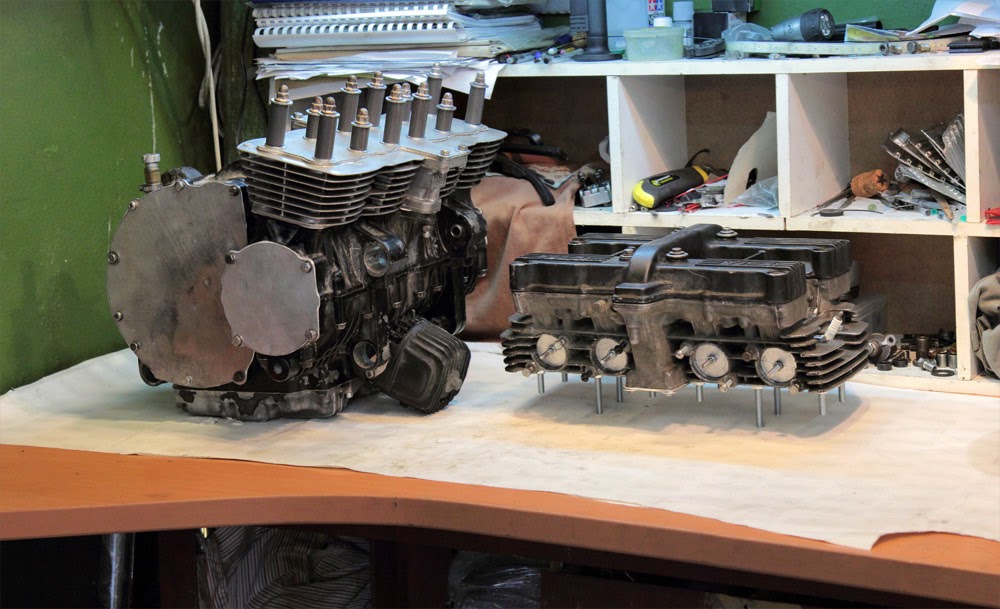

While first portion of parts was in painting, I took out engine and placed it on the working table.

While first portion of parts was in painting, I took out engine and placed it on the working table.

It’s well known, old engines need at least inspecting and rebuilding of a top end. I got a minimal kit (gasket set and rings) for that in last couple of parcels.

It’s well known, old engines need at least inspecting and rebuilding of a top end. I got a minimal kit (gasket set and rings) for that in last couple of parcels.

But this engine I have prepared for repainting, so it was completely disassembled.

But this engine I have prepared for repainting, so it was completely disassembled.

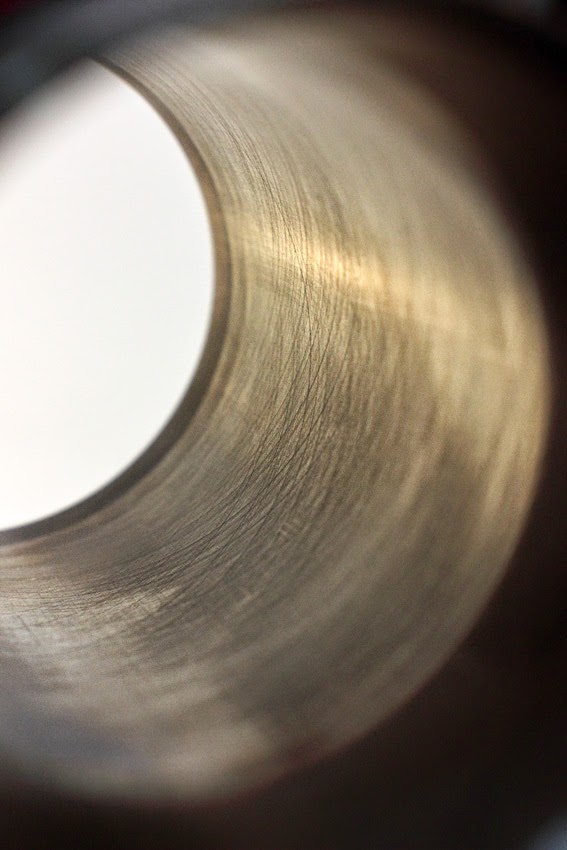

Thorough inspection of components had shown that all of them were in good condition, except of a bit rusted metal clutch disks and a slight deviation from norm in first cylinder measurements. It was out-of-round in 0.07mm while specification limit was 0.05mm.

Thorough inspection of components had shown that all of them were in good condition, except of a bit rusted metal clutch disks and a slight deviation from norm in first cylinder measurements. It was out-of-round in 0.07mm while specification limit was 0.05mm.

I was forced to research of the XJ600 51J cylinder block replacement, and defined it to be interchangeable with Diversion 600 one. That was possible with some modifications related with cam chain adjusting system. And Diversion block had lager cooling fins as a bonus. Therefore, I bought cylinder block on ebay.

I was forced to research of the XJ600 51J cylinder block replacement, and defined it to be interchangeable with Diversion 600 one. That was possible with some modifications related with cam chain adjusting system. And Diversion block had lager cooling fins as a bonus. Therefore, I bought cylinder block on ebay.

Cylinder head inspection also revealed a need of light porting.

That was usual work which I did without problems.

That was usual work which I did without problems.

When parcel with cylinders arrived, I did all needed measures to be sure in bores good condition.

When parcel with cylinders arrived, I did all needed measures to be sure in bores good condition.

But they were near perfect condition.

But they were near perfect condition.

I performed all needed modifications to install new cylinders in my engine, after that I cleaned engine and prepared it for glass blasting.

I performed all needed modifications to install new cylinders in my engine, after that I cleaned engine and prepared it for glass blasting.

Engine looked very nice and clean after aforesaid procedure and was ready for painting.

Engine looked very nice and clean after aforesaid procedure and was ready for painting.

Project progress gained momentum and seemed to be on full throttle…

Project progress gained momentum and seemed to be on full throttle…