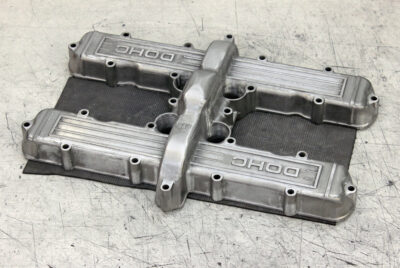

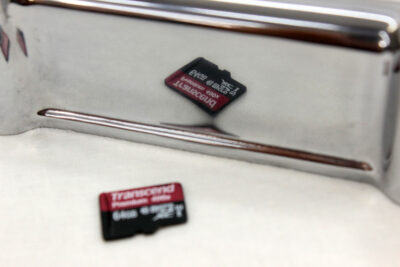

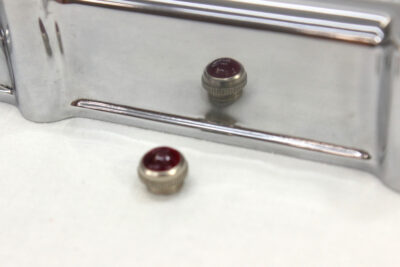

Before starting Kawasaki KZ650 engine assembling I have a couple of works to do. One of them is engine covers polishing. I want to get them ready so that after assembling the engine will be stored not only completely ready, but also sealed. And here is the first ready unit: valve cover. It is also the hardest cover to polish due to its configuration, design (which also includes DOHC lettering) and condition. It is a 40 years old cover which was in use for a long time, and was some time ago glass beads blasted. The casting of cover is accurate, but it never was intended to be polished, and unevenness of casting alloy didn’t make things easier. It took me a lot of effort and work to make the cover looks decently. To show you a contrast between “before” and “after” here is a couple of pairs of photos:

And here some detailed photos of how cover looked before I started to work on it:

And here some detailed photos of how cover looked before I started to work on it:

From the first movements of sandpaper it was obvious what amount of work lay ahead.

From the first movements of sandpaper it was obvious what amount of work lay ahead.

Preparation for polishing is a work that requires patience. The path of using coarse sandpaper may look more attractive and fast, but one who takes it will end up with a result which is far from perfect, or having even more work removing scratches from coarse sandpaper. So progress was slow.

Preparation for polishing is a work that requires patience. The path of using coarse sandpaper may look more attractive and fast, but one who takes it will end up with a result which is far from perfect, or having even more work removing scratches from coarse sandpaper. So progress was slow.

However, after a lot of dry and wet sandpapering cover began to look much better. It was mostly ready for polishing.

However, after a lot of dry and wet sandpapering cover began to look much better. It was mostly ready for polishing.

This time polishing was also tricky because I had a lot of corners and tight spaces to process. I did my best and I went right to the edge, after which the time spent on improving the result tends to head toward infinity, while improving itself heads in the opposite direction. So here is, polished Kawasaki KZ650 valve cover, fresh after polishing:

This time polishing was also tricky because I had a lot of corners and tight spaces to process. I did my best and I went right to the edge, after which the time spent on improving the result tends to head toward infinity, while improving itself heads in the opposite direction. So here is, polished Kawasaki KZ650 valve cover, fresh after polishing:

Letters gave me quite a headache.

Letters gave me quite a headache.

Some additional “after” photos to make a contrast to those detailed “before” photos:

Some additional “after” photos to make a contrast to those detailed “before” photos:

Now I am working on the other covers…

Now I am working on the other covers…

Hey. Love your work. I hope you’re ok and your loved ones are safe. If you can find the time can you tell me a product to seal or protect the polished alloy surfaces? Also is there a different product to protect hot alloy surfaces?

Stay safe .