I made my readers wait for new story about Honda CB750 Seven Fifty cafe-racer, but I hope this article itself will be sufficient apology for this delay.

So, what could hold me for a while? It may sound funny, but that were passenger foot-pegs. After I completed all my part in painting I had to do the next two branches of work:

- Preparation of aluminium chassis parts (like swingarm, wheel hubs, etc.) for glass blasting and therefore for the following painting.

- Frame works.

Initially I started with first branch and mostly finished it, but as my painter was busy and didn’t finished tank and fenders in time, I had to put it aside and start frame works.

Some of those works were quite obvious: to cut off from frame all those bits that were no longer needed, to weld the tail to the sub-frame and to grind all what needed to be grinded and at last, to make all brackets and mounting plates and to welt ham rot to the frame too. Sounds like the mostly finished project, yea? But I had one obstacle on my way and that was a question of passenger foot-pegs. I abandoned thinking about them for a long, since I changed my mind and redesigned project as two-seater motorcycle, so it was a time to pay for that neglect.

Sure, after I carefully invented the design of this cafe-racer and invested so much a skill into its realization I couldn’t just take any universal foot rests and clamp them or weld them to the frame. Thus I had to design something that don’t break the lines of the bike and be completely in style with its design. My mind raced from one idea to another, but all of them were thrown aside before an idea of a foot peg that will partly enfold frame tube.

After some experiments with tubes I understood that only way to make such foot pegs is to draw them from the scratch. As a blank I choose 3mm stainless steel plate, therefore I needed some kind of press. I made improvised frame for it from what I found at hand in my garage and used hydraulic jack as a pressing unit.

With its help I U-shaped 3mm plate by pressing it into grooved wooden block. I used old pine bar and it turned out to be tough enough for such a purpose. As a result of my work I had a couple of U-shaped blanks.

With its help I U-shaped 3mm plate by pressing it into grooved wooden block. I used old pine bar and it turned out to be tough enough for such a purpose. As a result of my work I had a couple of U-shaped blanks.

I shaped them initially and drilled holes for pins:

I shaped them initially and drilled holes for pins:

But that was the easiest part of work. My main goal was to make fully featured foot pegs. That meant automatic fixation of foot-pegs in opened and closed positions and should not require additional efforts from its user. This task was a kind of challenge for my engineering skills, but I successfully designed the system and made it in metal.

But that was the easiest part of work. My main goal was to make fully featured foot pegs. That meant automatic fixation of foot-pegs in opened and closed positions and should not require additional efforts from its user. This task was a kind of challenge for my engineering skills, but I successfully designed the system and made it in metal.

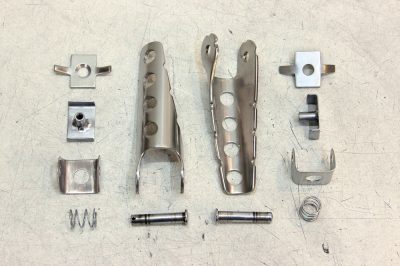

The set of foot-pegs reply parts for frame:

And parts of foot rest mechanism:

And parts of foot rest mechanism:

I made most of them from stainless steel as foot-pegs themselves, and those that are from ordinary steel will be later zinc-anodized.

I made most of them from stainless steel as foot-pegs themselves, and those that are from ordinary steel will be later zinc-anodized.

After I worked out this mechanism I finally shaped foot-pegs and finished their design.

I made my foot rests of the size to be quite close to standard, here you may see them in comparison to Kawasaki Zephyr foot peg:

I made my foot rests of the size to be quite close to standard, here you may see them in comparison to Kawasaki Zephyr foot peg:

Wish to know how it works? See my next post in a couple of days!

Wish to know how it works? See my next post in a couple of days!

Incredible work !!! wouahhhhhhhhhh