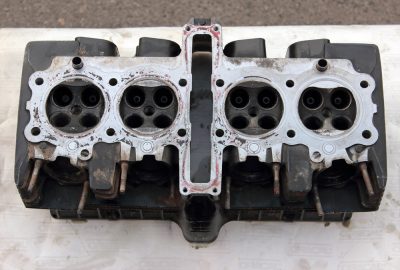

As I wrote earlier, I used CBX750 cylinder head and camshafts in this my Honda Cb750 Seven Fifty cafe-racer project. And even as all components were checked and turned out to be in sound condition, still there were a lot of work to do. Thirty years old carbon deposits with their deepest mostly fossilized layers could be hard to remove. And to be honest, sometimes I think Honda have been used sand casting technologies up until now… CBX750 cylinder head has sixteen valves, so channels are tight and intake channels are awfully deep in addition.

On this background carbon deposits on valves may look like easy game.

On this background carbon deposits on valves may look like easy game.

However, unscrewing of Honda CBX750 exhaust studs with their 6mm to 8 mm change of thickness gave me a real headache, even with welding involved…

However, unscrewing of Honda CBX750 exhaust studs with their 6mm to 8 mm change of thickness gave me a real headache, even with welding involved…

But I used to this kind of work, so I did rather cleaning than porting work to cylinder head channels, cleaned valves and won the battle for unscrewing exhaust studs. After it was finished I gave cylinder head and valves to the special machining shop which specializes on cylinder boring and cylinder head components works.

But I used to this kind of work, so I did rather cleaning than porting work to cylinder head channels, cleaned valves and won the battle for unscrewing exhaust studs. After it was finished I gave cylinder head and valves to the special machining shop which specializes on cylinder boring and cylinder head components works.

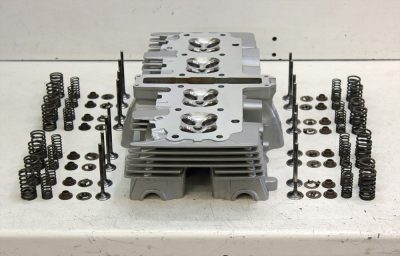

I ordered cylinder head surface grinding, valve seats refacing and valve face machining. May be that’s not the best cylinder head work I have ever done, but anyhow, after my efforts and machining all parts looked much better than before:-)

When I prepared engine for assembling I cleaned and sorted all required components for every valve installation.

When I prepared engine for assembling I cleaned and sorted all required components for every valve installation.

What else we need? Of course, OEM valve seals.

What else we need? Of course, OEM valve seals.

Special tool, molybdenum grease and engine oil.

Special tool, molybdenum grease and engine oil.

My tool worked, as always, perfectly, so I easily installed valve by valve.

My tool worked, as always, perfectly, so I easily installed valve by valve.

Little trick: washer made of plastic oil can to make process smooth.

Little trick: washer made of plastic oil can to make process smooth.

And here it was, first ready engine unit.

And here it was, first ready engine unit.

Is it true the firing order on the rc17 and rc42 engine differ?

I am building an rc42 and planning on the rc42 crank, rc17 gearbox, rc17 head and rc42 cams. I would prefer to use rc17 cams but with the firing order being different do you know if the rc42 cams bolt into the rc17 head ok?

thanks

matt

Hi Matt,

Sorry for late answer. I am about to finish assembling of my bike so I have too little time for internet.

I think it is rather a myth caused by misprint in manual. Right firing order is 1-2-4-3. The thing is simple, engine has spark simultaneously in pair of cylinders: 1-4, 2-3. So which cylinder fire (first of fourth, second or third) depends only on cams’ lobes position at the moment of spark. Thus, to have different firing order RC17 and RC42 must have camshafts with different lobes positioning. I do not recall any such difference nor could find it on photos from internet.

And even if RC17 firing order was as it indicated in manual 1-3-4-2, you still could use RC17 head and camshafts with RC42 bottom as it make no difference for ignition system.

Kind regards,

Nazar

Thanks a lot Nazar.

That clears things up for me.

Loving the build!

Interesting write up!

Is there a difference between CBX750 and CB750 Valves?

My project bike has 5 bent exhaust valves, and I’m looking for replacement.

Thanks!

Hi,

Sorry for late reply.

CBX750 and CB750 valves aren’t interchangeable. CBX750 valves’ have heads of larger diameter then CB750 valves.

Kind regards,

Nazar